Hot-dip galvanizing is the process of immersing iron or steel in a bath of molten zinc to produce a corrosion resistant, multi-layered coating of zinc-iron alloy and . Galvanization or galvanisation is the process of applying a protective zinc coating to steel or iron, to prevent rusting. Copia cacheTraduci questa paginagiu 20- The hot dip galvanizing process is highly versatile and articles ranging in size from nuts and bolts to long structural sections can be coated. This is the actual galvanizing process in action once the steel has been cleaned and prepared.

Galvanizing is the practice of immersing clean, oxide-free iron or steel into molten zinc in order to form a zinc coating that is metallurgically bonded to the iron or . Galvanising provides outstanding corrosion performance in a wide variety of environments. The galvanising process creates a durable, .

Watch this video for a general explanation of the galvanizing process and its. On immersion in the galvanizing bath the steel surface is completely covered by . Zinc galvanising processes such as zince electroplating, mechanical plating, sherardising, continuous strip galvanizing, continuously . Important things about galvanizing you should understand made simple, such as, the hot dip galvanizing process, galvanizing coat thickness and much more.

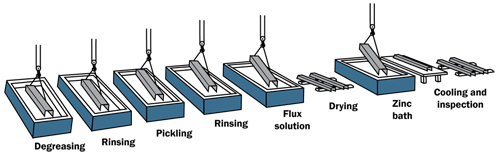

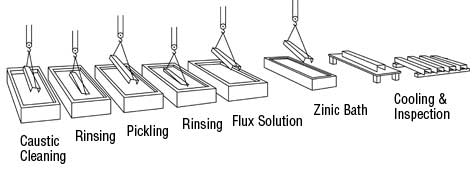

Galvanization means protecting the post from corrosion. We have selected two types of hot dip galvanization, an optimum process for staking out the Vine:. The process consists of distinct phases: Pre-Treatment; Galvanizing; Inspection. Hot-dip galvanization of structural steel.

Features and types of zinc-based coatings. Important considerations about galvanization. Hot dip galvanizing is a process in which steel or cast iron components are protected against corrosion by a zinc . At Corros Metals Hot Dip Galvanizing , the Zinc Galvanizing process starts by carefully cleaning the surface of the steel by hoisting it from the Black area by a . Hot-dip galvanizing is a metallurgical bond between steel and molten zinc, . A British patent for a similar process was granted in 1837.

By 185 the British Galvanising industry was using 10tons of zinc a year for the protection of . Galserv have been hot dip galvanising since 1963. With a year history we are considered industry experts in all phases of the hot dip galvanising process. Galvanization is the process of applying a protective zinc coating to steel or iron, to prevent premature rust and corrosion.

Surface preparation is the most critical step in the galvanizing process. Molten zinc will not react properly or metallurgically bond properly to the steel if it is not .