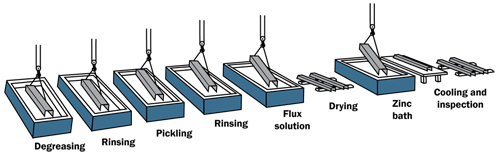

Hot-dip galvanizing is the process of immersing iron or steel in a bath of molten zinc to produce a corrosion resistant, multi-layered coating of zinc-iron alloy and . Galvanization or galvanisation is the process of applying a protective zinc coating to steel or iron, to prevent rusting. Copia cacheTraduci questa paginagiu 20- The hot dip galvanizing process is highly versatile and articles ranging in size from nuts and bolts to long structural sections can be coated. This is the actual galvanizing process in action once the steel has been cleaned and prepared. Galvanizing is the practice of immersing clean, oxide-free iron or steel into molten zinc in order to form a zinc coating that is metallurgically bonded to the iron or . Watch this video for a general explanation of the galvanizing process and its. On immersion in the galvanizing bath the steel surface is completely covered by . Whereas its combination of strength and formability, as well as the abundance of iron ore, has made steel one of modern . Solid metallic particles are washed out of galvanized products surface and transfer of.

This stage serves as temperature preparation for galvanizing process. Hot dip galvanizing is the process of applying a zinc coating to fabricated steel. The galvanized coating provides both barrier and cathodic protection against .